Tag Archives: drilling waste management

OBM Drilling Waste Management Shipment

As the professional manufacturer in China, TR Solid Control could design and manufacture various model Drilling Waste Management or or Cutting Dryer System according to the customers requirement. On May.10th, one new batch of oil based drilling waste management was shipped to our old customer. Currently this system is widely used in Chinese domestic market for compact structure and high efficiency.

This system is composed of TRCD930C vertical cutting dryer, TRLW355N-1 high speed centrifuge, mud tank, centrifuge supply pump and other auxiliary accessories. Processing capacity of our dryer could reach up to 30-50 T/h with basket diameter 930mm. Rotary speed is 900r/min. Bowl diameter of our TRLW355N-1 centrifuge is 350mm, and bowl length is 1250mm. Processing capacity is 40m3/h. TR drilling waste management system can effectively control the moisture content (6%-15%) and oil content (2%-8%) in drilling cuttings, and stabilizes the liquid phase performance.

TR Solids Control is one of the most famous international brand for Mud Solids Control System & Drilling cuttings Management in China. We have one stop service for Solids Control Solution of your oil gas drilling, CBM drilling, HDD, and water well drilling as well as the construction drilling mud treatment etc. For more information about our drilling waste management, please visit: https://trsolidscontrol.en.made-in-china.com/

Drilling Waste Management Perform Well in Singapore Field

Recently, TR independent R&D drilling waste management has received favorable evaluation from customer at the drilling site in Singapore. Feedback from customer said that TR skid-mounted drilling waste management performs well. It provides an effective solution for them to treat slurry and waste in the pit on their rig site. They are considering starting up the further cooperation with us by placing order on TR module type oil sludge treatment system with large handling capacity.

TR drying shaker

This drilling waste management chosen by our Singapore client is relatively simple. It is divided into two units-waste collection unit and liquid phase separation unit. Waste collection unit consists drying shaker, screw conveyor, mud collection tank, mud agitator etc. Its working principle is transferring the waste residue treated by shale shaker, desander, desilter and decanter centrifuge to the high-frequency drying shaker through screw conveyor. Big particle cuttings in solids control equipment are separated, and liquid enters collection tank for buffering and pretreatment. Liquid separation unit is mainly composed of a program-controlled diaphragm filter press. Solid phase particles are finally separated by a filter press. Separated solid phase can be directly transported. Liquid phase can be carried to the mud circulation system for reuse through mud sand pump.

Drill cutting treatment system

The emergence of drilling waste management has successfully solved the problem of inefficient disposal of drilling waste. TR Solids Control is a lead and professional manufacturer of drilling waste management in China. We have unique slurry treatment solution in oil exploration, sewage treatment, bored piling, and horizontal directional drilling. Contact with us for more details now!

Web: http://www.trsolidscontrol.com/

http://tianruisolidscontrol.ecer.com

Email: sunny@trsolidscontrol.com

Choosing Good Shaker Screen Is Important

Shale shaker screen is very important in the drilling cuttings separation process.Shale shaker is first stage separation equipment in drilling mud cleaning system.In some sense,the shaker screen quality may determine the separation effect of one shale shaker.The separation effect of the shale shaker also has enormous impact on the following separation equipment’s working result,such as desander,desilter,decanting centrifuge,etc.

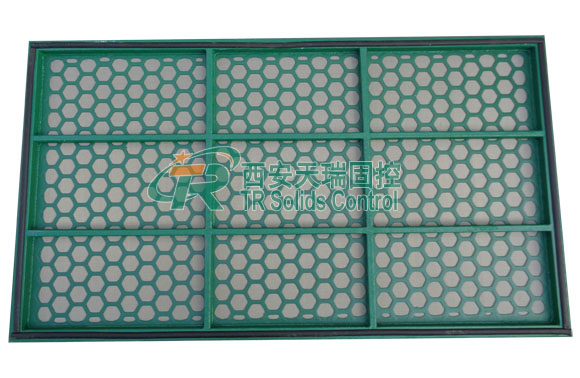

shale shaker equipped with composite frame screen

TR series of shale shaker is divided into linear motion shale shaker and balanced elliptical motion shale shaker.According to different situation and mud content,applied different structure and equipped different type & quantity shale shaker screen.For example,the TR drying shaker is designed with an 8.5G vibration force and 4 pieces of frame shaker scree to get a better drilling cuttings drying effect. The frame screen is the most popular used screen at present.It possesses the advantages of good separation effect,easy to handle,etc.

Steel frame shaker screen

TR Solid Control is a professional manufacturer of solid control system and drilling waste management equipment.TR will provide you the most economic solution according to your working site and the drilling mud condition. Of course,TR will help you make correct choice from the complete solution to every equipment,together with the important vulnerable spare parts,like every piece of shaker screen.

Contact: Mark

Sales office:No.10 West of North 2nd Ring Road Xi’an City.

Manufacture: No.60 Caotang Industry Zone Huxian County Xi’an City.

Tel:+86-29-86332919

Call:+86-13186019379

What’s App:13186019379

E-mail: mark@trsolidscontrol.com