Tag Archives: shaker screen mesh size

How to Choose the Right Shaker Screen Mesh Size for a Shale Shaker?

The screen size of shale shakers is a critical factor influencing solids control efficiency in drilling operations. Selecting an appropriate screen size can optimize the separation effect of drilling solids, improve drilling fluid quality, and enhance overall operational performance. This article provides practical insights and guidance on how to choose the right screen size for shale shakers.

1. Understand the Basic Concept of Screen Size

Screen size is usually expressed in mesh count, which refers to the number of openings per square inch. A higher mesh count indicates smaller openings, meaning that finer particles can be separated. For example, a 200-mesh screen has smaller openings than a 100-mesh screen.

2. Consider Drilling Conditions and Formation Characteristics

Screen size selection should be combined with specific drilling conditions and the characteristics of the drilled formation, mainly including the following aspects:

- Formation Particle Size and Composition: Analyze the size and composition of solid particles in the drilled formation. Fine-grained formations typically require finer screens to achieve effective separation.

- Drilling Fluid Performance: The viscosity, density, and rheological properties of drilling fluid affect the sedimentation characteristics of solids, thereby influencing the required screen fineness.

- Drilling Conditions: Estimate the type and content of solids during drilling. If the content of fine particles is high, a screen with a higher mesh count should be selected.

3. Evaluate Shaker Performance and Separation Point Requirements

Screen selection also needs to take into account the performance characteristics of the shale shaker itself:

- Screen API Designation: Shaker screens are usually marked with API designations, indicating the particle size range they can effectively separate. For instance, an API 60 screen can separate particles larger than 250 microns.

- Separation Point Requirements: Determine the target separation point according to the solids control precision required for drilling operations. A smaller separation point calls for a screen with a higher mesh count.

4. Refer to Manufacturers’ Recommendations and Industry Standards

Shale shaker manufacturers usually provide screen selection guides, which should be prioritized to ensure equipment compatibility and performance optimization. Meanwhile, relevant industry standards and regional specifications must be followed.

5. Incorporate Field Experience and Test Verification

Drawing on field experience under similar drilling conditions, or conducting tests when necessary, helps verify the actual performance of different screens. Communicating with drilling experts and carrying out field tests can facilitate the selection of the most suitable screen size for specific operating conditions.

6. Balance Processing Efficiency and Solids Control Precision

Screen selection requires a balance between separation efficiency and processing capacity. Although a finer screen can improve separation precision, it may reduce processing throughput and increase the risk of screen clogging. It is essential to balance solids control effectiveness with drilling fluid circulation requirements to maximize operational efficiency.

Conclusion

Rationally selecting the shale shaker screen size is a key step to enhance solids control effectiveness and drilling operation efficiency. Scientific selection decisions can be made by comprehensively analyzing drilling conditions, formation characteristics, and equipment performance, as well as referencing industry experience and standards. Finding the optimal balance among separation precision, processing capacity, and operational efficiency will effectively improve drilling fluid quality and ensure the smooth progress of drilling operations.

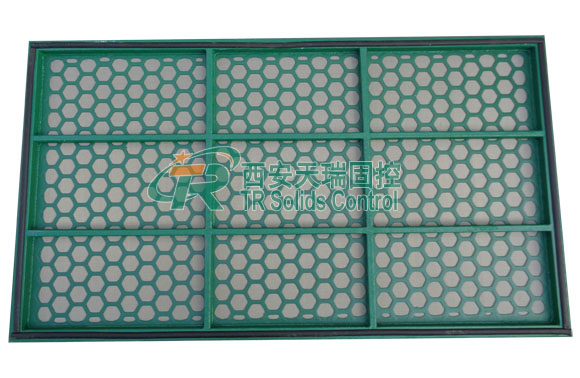

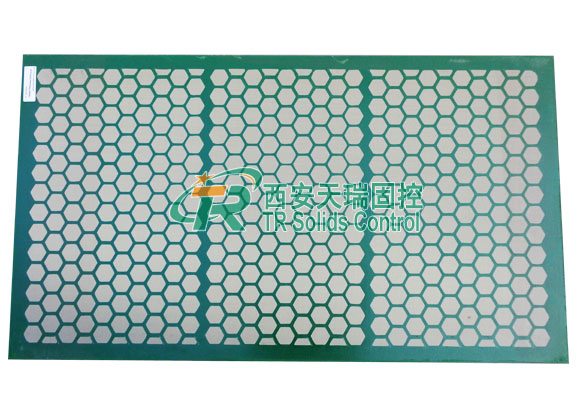

TRF series Steel frame shale shaker screen

TRF series Steel frame shale shaker screen

Frame shaker screen is one commonly used in oil drilling mud shaker screen,sometimes called rock shaker screen.There are two kinds of frame according to the frame material:steel frame and composite frame. TRF series of shale shaker screen refers to the steel frame ones.The shaker screen design is mainly composed of the steel frame and 2 to 3 layers of screen cloth. The stainless steel screen frame is made of high strength square steel or flat steel with reinforced support bars. The screen cloth can be joined to the frame by metal liner or directly bonded to the frame. According to the needs of different customers,TR can supply a variety of specifications of the size of the steel frame screen.

Steel frame screen maufuacturer|china Steel frame screen supplier

Features: wearable, corrosion resistance, high temperature resistance

Specifications: Thickness: 0.3-8mm, short pitch: 3-80mm, long pitch: 3-200mm, the largest width: 2.0mm;Shaker screen mesh size:40-325.

Material: can be divided into ordinary carbon steel, stainless steel, iron, copper, aluminum, titanium, nickel, and so on.

Steel frame shaker screen supplier

TRF Series Steel Frame Shaker Screen Size Chart

| Model | Model for Shaker | Mesh Range | DimensionLxW(mm) | Weight(kg) |

| TRF-1 | BRAANDT BL-50 | 40-325 | 1253X635 | 13.5 |

| TRF-2 | BRANDT VSM300 | 40-325 | 913X650 | 12.6 |

| TRF-3 | SWACO MONGOOSE | 40-325 | 1165X585 | 14 |

| TRF-4 | KENTRON 48 SERIES | 40-325 | 1120X720 | 17.5 |

| TRF-5 | SF300 | 40-325 | 712X1180 | 15 |

| TRF-6 | TRZS703 | 40-325 | 1250X700 | 13 |

| TRF-7 | TRZS852 | 40-325 | 1250X850 | 16 |

| TRF-8 | TRZS752 | 40-325 | 900X750 | 10 |

TR Solid Control is one professional shaker screen manufacturer and exporter specialized in oil drilling solid control equipment and system.TR shaker screen are divided into frame screen,hook strip screen,hook strip soft screen.TR solid control can also provide customized screen and the replacement of Derrick,Swaco and Brandt.TR is your best choice in solid control equipment and shaker screen.

Contact: Mark

Sales office:No.10 West of North 2nd Ring Road Xi’an City.

Manufacture: No.60 Caotang Industry Zone Huxian County Xi’an City.

Tel:+86-29-86332919

Call:+86-13186019379

What’s App:13186019379

E-mail: mark@trsolidscontrol.com